HIL Software Testing, or Hardware-in-the-Loop testing, has become a game-changer in the embedded systems industry. Companies like Servotech are leveraging this approach to enhance product quality and streamline development processes. In this article, we explore how HIL software testing significantly boosts product quality while reducing overall development time.

What is HIL Software Testing?

HIL Software Testing is an advanced testing method used to validate embedded systems. It involves simulating real-world conditions in a controlled environment, where the software interacts with a virtual representation of the hardware components. This approach allows engineers to test and refine software without the need for physical prototypes, saving time and resources.

Why HIL Testing is Essential for Embedded Systems

Embedded systems are critical in various industries, from automotive to aerospace. Ensuring their reliability and performance is paramount. HIL testing provides a robust platform to verify and validate these systems before they are deployed. By identifying issues early in the development cycle, HIL software testing helps avoid costly fixes and ensures that the final product meets high-quality standards.

Key Benefits of HIL Software Testing

1. Early Detection of Software Bugs

One of the primary advantages of HIL software testing is the early identification of software bugs. Testing in a simulated environment allows engineers to detect and address issues before they escalate. This proactive approach significantly improves the reliability of the software.

2. Enhanced Product Quality

HIL software testing ensures that the product undergoes thorough validation against various real-world scenarios. By simulating different operating conditions, it helps uncover potential failures that might not be evident in traditional testing. This comprehensive testing process leads to higher product quality and customer satisfaction.

3. Reduced Development Time

By using HIL software testing, companies can eliminate the need for multiple physical prototypes. Simulations can be conducted at various stages of development, reducing the overall time spent in the testing phase. This efficiency allows teams to deliver products faster to the market without compromising quality.

4. Cost Savings

The traditional approach of testing embedded systems can be expensive due to the need for physical prototypes and extended testing phases. HIL software testing minimizes these costs by using virtual models. This reduction in expenses is especially beneficial for companies looking to optimize their budgets while maintaining high standards.

5. Improved Safety and Compliance

In industries like automotive and aerospace, safety is a top priority. HIL testing helps ensure that software meets safety and regulatory standards by validating its performance in simulated hazardous conditions. This thorough testing is crucial for achieving compliance with industry regulations.

How Servotech Implements HIL Software Testing

At Servotech, the focus is on delivering high-quality embedded software solutions. By integrating HIL software testing into their development process, Servotech can thoroughly test and validate their software before it reaches the client. This approach not only enhances product reliability but also accelerates the development cycle, enabling faster delivery times.

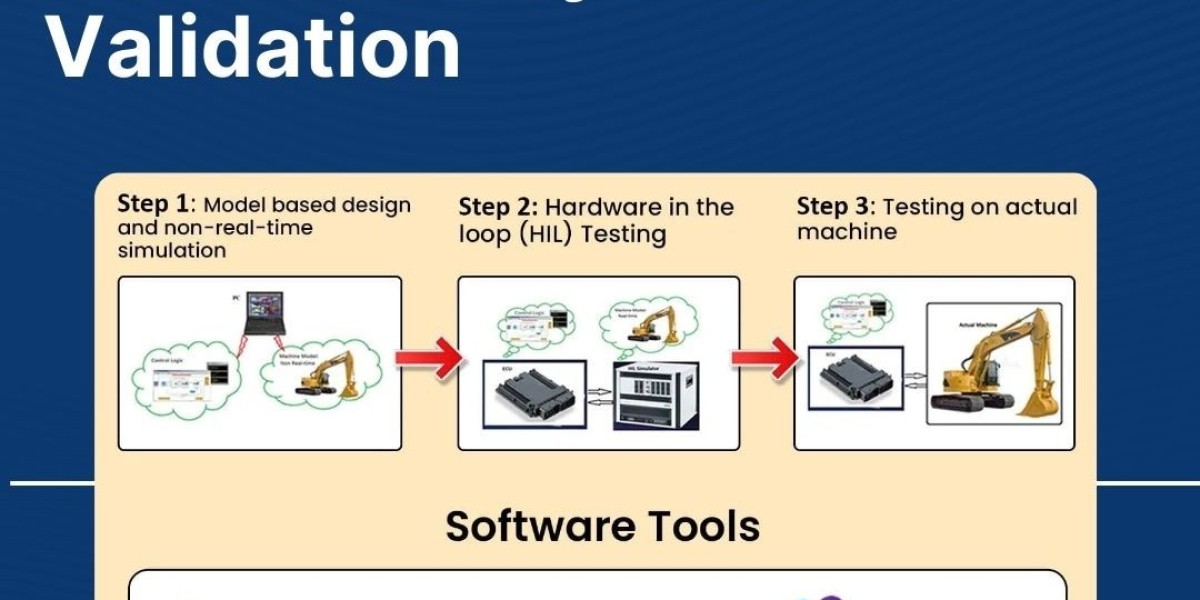

Step-by-Step Process of HIL Testing at Servotech

Model Creation: Engineers create a detailed virtual model of the hardware components.

Simulation Setup: The software is integrated into a simulated environment.

Testing Scenarios: Various operating conditions and stress tests are simulated to evaluate software performance.

Data Analysis: Results are analyzed to identify any issues or areas for improvement.

Refinement: The software is refined based on the test results, ensuring optimal performance.

Applications of HIL Software Testing

HIL testing is widely used in several industries:

Automotive: For testing electronic control units (ECUs) in vehicles.

Aerospace: To validate flight control systems and ensure safety.

Industrial Automation: For verifying control systems in manufacturing processes.