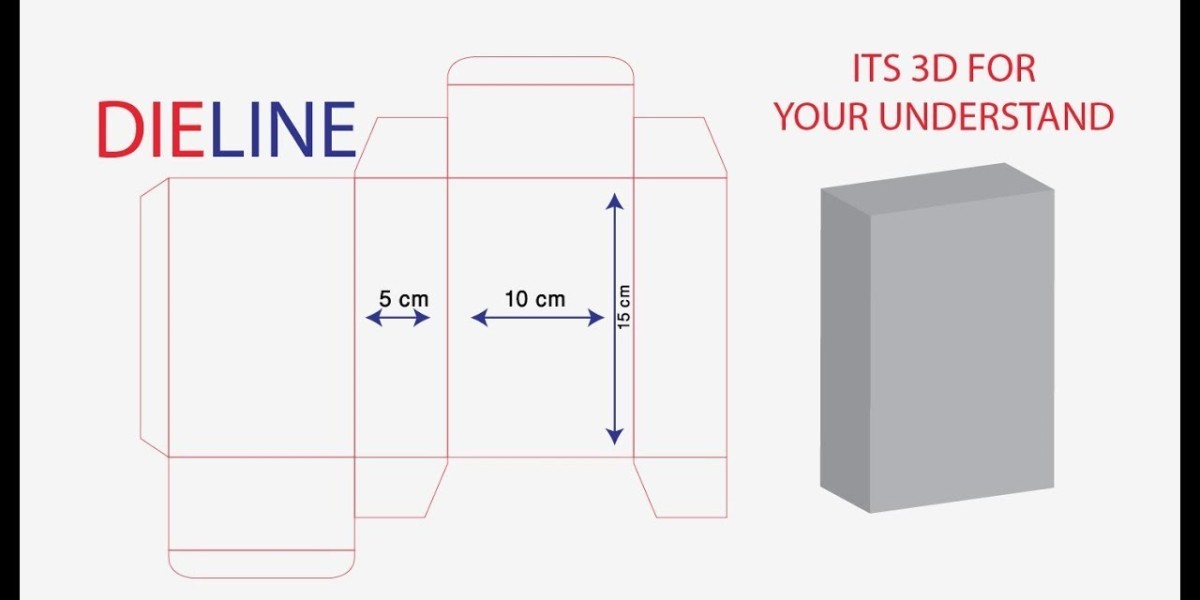

A dieline is a template that outlines the dimensions, cuts, folds, and design elements of a packaging product. It acts as a blueprint for designers and manufacturers, ensuring that the final packaging accurately reflects the intended design while being functional and manufacturable.

The Importance of Dielines in Packaging Design

Dielines play a significant role in the packaging design process. They ensure that all aspects of the packaging, from structural integrity to aesthetic appeal, are addressed before production begins. A well-crafted dieline minimizes errors and streamlines the workflow, ultimately saving time and costs associated with revisions.

Key Components of a Dieline

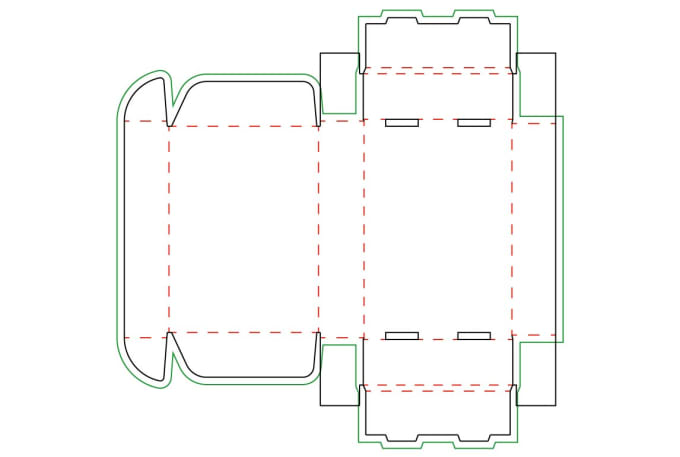

A typical dieline consists of several critical elements:

Cut Lines: These are the lines where the packaging will be cut. Understanding the cut lines is essential to avoid any misalignments during production.

Fold Lines: Indicating where the packaging will be folded, these lines ensure that the structure can hold the product securely.

Bleed Area: This is the area beyond the cut lines that allows for any minor misalignments in printing. Including a bleed area is vital for achieving a professional finish.

Registration Marks: These marks help in aligning the print correctly during the printing process, ensuring that colors and designs line up perfectly.

Text and Graphics Placement: The dieline also indicates where text and graphics will be placed on the packaging, making it easier for designers to visualize the final product.

Creating an Effective Dieline

To create an effective dieline, several steps should be followed:

Identify the Packaging Type: Understand the type of packaging required, such as boxes, bags, or labels, as each has unique requirements.

Measure Dimensions: Accurate measurements are critical. Use precise dimensions of the product to ensure a perfect fit.

Choose Materials: Different materials may require different dieline specifications. For instance, cardboard packaging will differ significantly from plastic packaging.

Design Software: Utilize design software like Adobe Illustrator or CAD tools to create your dieline. These programs offer templates and tools to ensure accuracy.

Prototype Testing: Before finalizing, create a prototype to test the design’s functionality and aesthetics. This step can highlight potential issues before going into full production.

Common Mistakes to Avoid in Dieline Creation

When creating dielines, avoiding common pitfalls can significantly improve the outcome:

Inaccurate Measurements: Double-check all measurements to prevent costly mistakes during production.

Ignoring Fold Lines: Ensure that fold lines are marked clearly and accurately to prevent misalignments.

Not Considering Material Thickness: Material thickness can affect the final design. Be sure to account for it when designing the dieline.

Omitting Registration Marks: These marks are essential for multi-color printing. Failing to include them can result in color misalignment.

The Role of Dielines in Brand Identity

A well-designed dieline contributes significantly to a brand’s identity. Packaging is often the first point of contact between a consumer and a product. An appealing and functional package can enhance brand perception and drive sales.

Visual Appeal: A creatively designed dieline can attract attention on the shelves, making the product stand out among competitors.

Functional Design: Ensuring that the packaging is not only beautiful but also functional can enhance user experience and promote customer loyalty.

Consistency Across Products: A standardized dieline across product lines helps maintain a cohesive brand image, making it easier for consumers to recognize the brand.

Final Thoughts on Dielines in Packaging

In conclusion, understanding what a dieline is in packaging and its importance can greatly impact the success of product launches. A well-constructed dieline not only ensures that the packaging is aesthetically pleasing but also that it functions properly and represents the brand effectively.

By following best practices in dieline creation and recognizing its significance, businesses can enhance their packaging design process, ultimately leading to better market performance and customer satisfaction.